- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

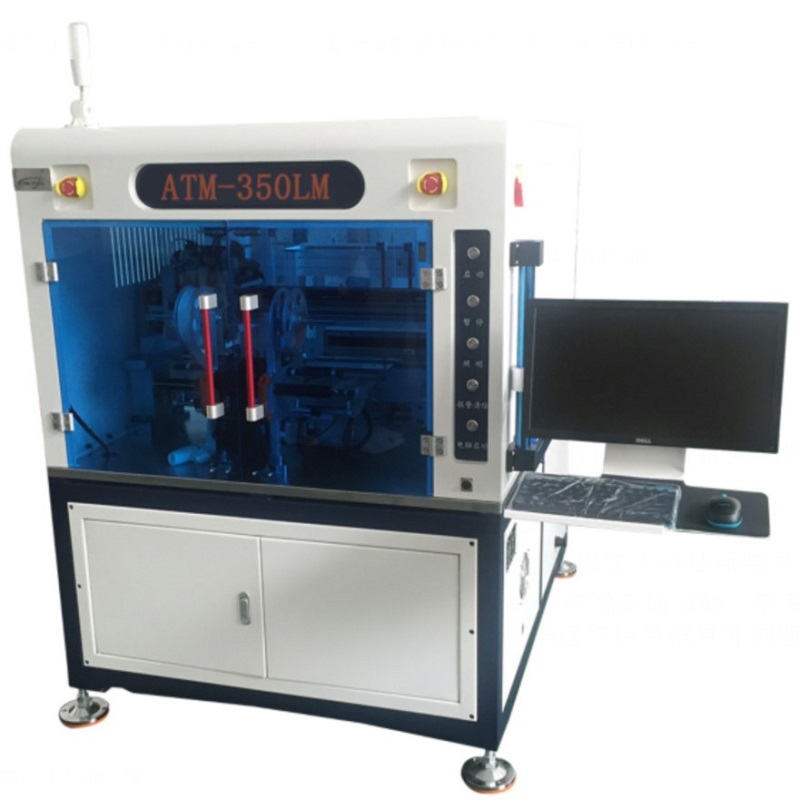

Atm-250ne Standard Automatic Paste Accessories Machine Equipment

- Product:Atm-250ne Standard Automatic Paste Accessories Machine Equipment

- Catalogue:Labelling machines

- Views:409times

- Update:2022/5/19 14:58:56

- Call:133-6065-4218

Atm-250ne Standard Automatic Paste Accessories Machine Equipment

Atm-250ne standard automatic paste accessories machine equipment is our company according to customer independent research and development production of small cost-effective paste accessories machine, with high speed and high precision paste accessories, small footprint, can greatly improve customer paste accessories capacity. It is widely used in soft and hard board of FPC and PCB industry of electronic industry, screen of 3C industry such as mobile phone and accessories on hardware and plastic shell.

Equipment introduction

Model: ATM-250NE standard automatic paste accessories machine

Configuration:

Two mounting heads; A maximum of two feeder hooks can be attached

Equipment functions:

◎ Suitable for SMT industry all kinds of need to label, adhesive, self-adhesive circuit board;

◎ Improve SMT online labeling machine capacity;

◎ Greatly reduce the operator labeling error rate;

◎ Make SMT line smoother and more efficient;

Standard automatic paste accessories machine hardware description:

1.X/Y motor adopts Japanese brand private service motor, high-performance linear module, high-precision CCD and supporting software to fully ensure the accuracy and stability of the machine;

2. High rigidity integrated steel frame structure ensures the stability of equipment under long-term high-speed operation;

3. High resolution camera and stable vision software, stable and efficient positioning algorithm, to ensure high speed production accuracy;

CCD identification standard Mark point positioning

1. The head camera can accurately position the product to ensure the accuracy and stability of the fitting coordinates.

2. The bottom camera locates the contour of the laminating material to ensure accuracy and stability.

3. After fitting, check whether to read the QR code and upload it to MES system.