- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

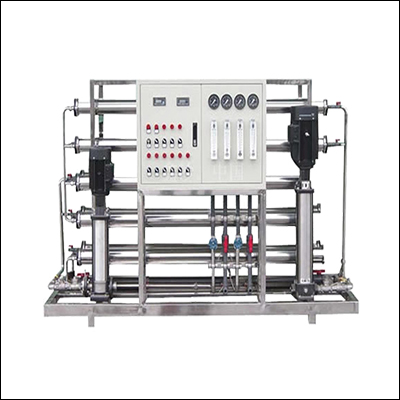

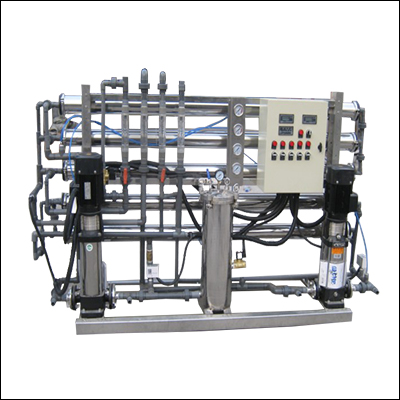

Water reuse in semiconductor production wastewater

- Product:Water reuse in semiconductor production wastewater

- Catalogue:Labelling machines

- Views:177637times

- Update:2018/10/10 12:01:30

- Call:133-6065-4218

I. Overview

For the semiconductor production wastewater, Qin Taisheng Water Treatment provides a complete wastewater treatment plan and wastewater reuse program. The system processes the semiconductor wastewater through the membrane bioreactor and the tertiary treatment system to achieve new strict environmental regulations. The actual reuse in the plant can not only effectively save limited water resources, but also reduce sewage. The emissions have good economic benefits.

The semiconductor production wastewater mainly comes from the plating tank and washing water in the workshop. The main pollutants contained in the wastewater are: Ag, Cu, Ni, COD, SS, CN, acid and alkali. The discharge of semiconductor production wastewater is large, the types of wastewater pollutants are numerous, and the composition is complex, especially the difference in content, pH and metal impurities of dissolved solids and suspended solids, which makes the reuse of semiconductor wastewater pose a challenge to conventional technical treatment.

The system processes the semiconductor wastewater through a membrane bioreactor and a tertiary treatment system to achieve new strict environmental regulations and is actually reused in the plant. The system not only can effectively save limited water resources, thereby reducing the consumption of water resources, alleviating the increasingly conflicting water shortages, reducing the discharge of sewage, reducing the pollution of surrounding water bodies, and improving the living environment of human beings. Wastewater recycling costs can be reduced to approximately RMB¥2 per ton. The recycled water can be supplied to the pure water system or directly reused in the production line. It has good economic benefits and can recover the initial cost within 1 to 3 years.

Second, the process characteristics:

1, three low one zero

The system has low sludge output, low odor output, low energy demand, and minimum or zero chemical requirements.

2. Resource utilization

The water reuse after treatment by the system meets the strict requirements of the factory water quality, and can be supplied to the pure water system or directly reused in the production line.

3, cost-effective

The system is easy to operate, anti-impact load, compact footprint, high stability, low running cost, and has been verified by a large number of successful cases.