- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

High-end automatic adhesive backing machine

- Product:High-end automatic adhesive backing machine

- Catalogue:Adhesive backing machine

- Views:178303times

- Update:2013/3/26 15:39:51

- Call:133-6065-4218

High-end automatic adhesive backing machine:

High-end automatic adhesive backing machine model: ATM-350C

High-end fully automatic adhesive backing machine configuration

Two mounting heads.

Up to four feeders

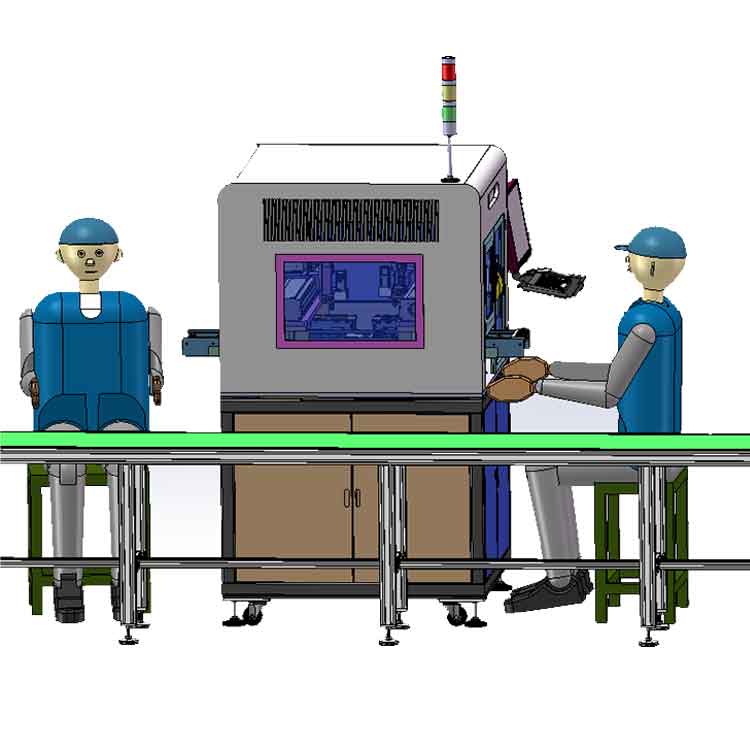

High-end automatic adhesive backing machine functions

High-end automatic adhesive backing machine is suitable for SMT industry for all kinds of circuit boards that need labeling, backing and self-adhesive.

High-end automatic adhesive backing machine to increase SMT line labeling machine capacity

High-end automatic adhesive backing machine significantly reduces operator error rate

High-end automatic adhesive backing machine makes the SMT production line more smooth and efficient. After labeling, the label information can be realistically scanned and fed back to the MES system.

High-end automatic adhesive backing machine hardware advantages:

X/Y motor adopts American imported Kollmorgen linear motor,

THK linear module, high precision CCD and supporting software to fully ensure the accuracy and stability

of the machine when running at high speed

The whole machine frame integrated casting type processing, ultra-high stability, flexible application,

industrial control system.

Standard with head high definition CCD for code reading, special cases can also be used according to

customer demand special barcode scanner for code reading T-axis CCD.

Equipped with a T-axis CCD, which is rare in the industry, the machine can position the material coming

out of the feeder while it is running.