- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

Battery laminating equipment

- Product:Battery laminating equipment

- Catalogue:Adhesive backing machine

- Views:178290times

- Update:2013/3/26 15:39:51

- Call:133-6065-4218

Battery Insulation Sheet Equipment Introduction:

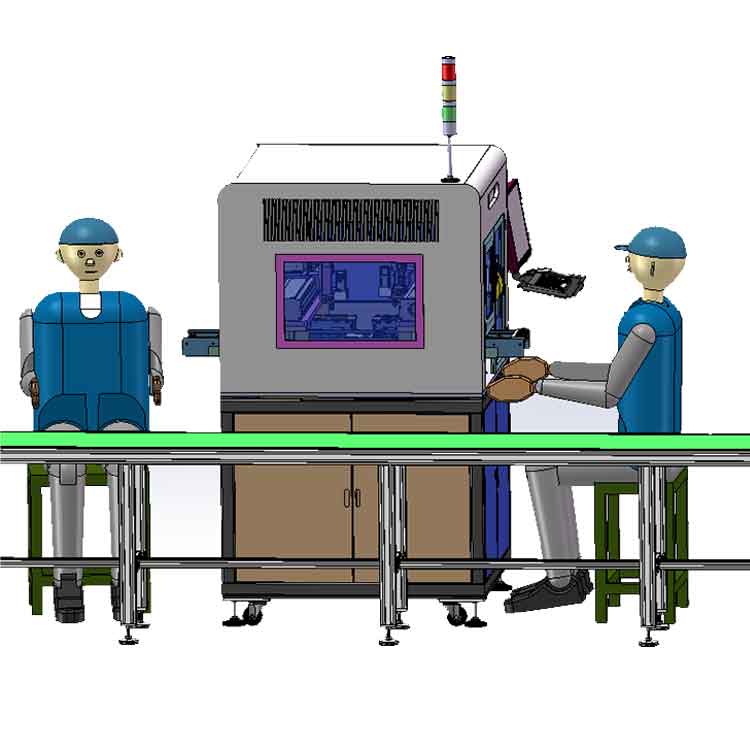

Equipment name: Automatic 18650 battery insulating sheet laminating equipment

Model: ATM-B18

Battery laminating insulating sheet equipment suitable for the production of complete boxes of 18650 batteries.

Operation can be completed by 1 person, manually placing the integrated battery inside the equipment, before laminating it can colleague to accommodate three boxes of batteries to be mounted, enhancing the flexibility of personnel involvement.

Battery laminating insulating sheet equipment is compatible with the production of three sizes of battery boxes, 38PCS, 50PCS and 100PCS; easy adjustment, three battery sizes are switched by quick plugging and unplugging, and the hardware is marked with three different specification markings for easy operation.

Battery box with clamping function in the process of applying insulation ring, preventing the battery from shaking around inside the box.

battery labelling insulating sheet equipment equipped with two sets of upper and lower CCD detection systems for precise placement of the labelled insulating ring.

accurate positioning of the label material tape and automatic alarm prompting after use.

The whole box slides onto the customer's desktop after the insulating ring has been applied at the receiving end, and the material is collected manually.

The whole machine is mobile, with castors + anti-vibration foot support, which makes it easy to move the machine and ensure its stability and reliability.

Features of the battery insulating sheet machine:

The Fei Da paddle assembly adopts precision stepping drive and high precision optical fibre to control the stability and accuracy

of the peeled material, and includes a vacuum adsorption structure for the backing paper to ensure a stable material discharge.

Servo motor: The Z-axis adopts servo motor to ensure high speed and high precision operation of the suction head to ensure

the speed and precision of the material.

Head vision: The Imaging Source camera is used to ensure the clarity of the head image and the compensation of the head

mark point.

Nozzles: two self-adhesive nozzles with quick release construction, allowing for the replacement of different nozzles for different

models The battery box tightening mechanism is compatible with 30, 48 and 100 boxes, the X/Y direction tightening

mechanism is simple and easy to adjust, the corresponding interface markings correspond to the product characteristics for

easy identification, the use of pins for easy operation, switching between different products, the wire change can be completed

within three minutes.