- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

Case

-

An electronics factory in dongguan ...

Design parameters

1. The amount of water

Water inflow: 15m /Hr

2. Inlet water quality

PH: 6.0 ~ 8.0

PC U: 3500 or less

COD: 50 PPM or less

Conductivity: ≤250 ° S/cm

3. Effluent quality

PH: 6.0 ~ 7.0

S.S. : < 5 PPM

COD: < 40 PPM

PCU: < 650

4. Production time of the factory: actual operation of the customer

Design principles and basis

1. Collect and treat the wastewater according to its characteristics;

2, the treatment project should be appropriate insurance coefficient, the choice of each process parameter is a little surplus;

3. The treatment facilities shall have a higher operating efficiency, and complete the process requirements with relatively stable treatment means;

4. In addition to meeting the technological requirements, construction investment and operation cost should be reduced as far as possible, and the equipment should be operated simply and reliably, maintained conveniently, operated and managed conveniently, and the labor intensity of workers should be minimized;

5. Develop and promote new technology and equipment with high efficiency, energy saving, easy management and easy operation, and good self-control level.

6, comprehensive planning, reasonable layout, reduce investment and operating costs.

The design and process of this set of equipment are customized according to customer requirements, the final interpretation right belongs to qin tai sheng water treatment all

...

-

Shenzhen certain hardware electroni...

Technical design guidelines

The design of this water treatment process is based on full consideration of the following factors:

2.1 users' requirements on the quality and yield of product water;

2.2 reliability of process design;

2.3 simplicity of equipment and intelligent operation;

2.4 investment and operating expenses;

2.5 physical and chemical cleaning of equipment;

2.6 stability of water quality;

2.7 reliable online monitoring means.

The system has requirements on the outside world

3.1 water supply: municipal tap water.

3.2 power supply: the user shall transmit the power cord to the electronic control cabinet of the equipment.

3.3 water production: the water produced by the supplier shall be connected to the ultra-pure water storage tank.

3.4 site: the user shall provide the equipment area.

3.5 drugs: all drugs consumed during debugging and operation shall be provided by users.

The technological requirements

4.1 raw water quality: ultrafiltration water produced after the wastewater reaches the standard (conductivity ≤2000us/cm)

4.2 effluent water quality: the conductivity of produced water after treatment is ≤100us/cm

4.3 system outlet water: the designed water yield of the system terminal is ≥8m3/h

Process diagram

Waste water → waste water station → raw water pump → multi-media filter → activated carbon filter →5um precision filter → ultrafiltration system → ultrafiltration production water tank → reverse osmosis raw water pump →5um precision filter → reverse osmosis high-pressure pump → reverse osmosis production water tank (the customer has) → back end water point

The design principle and process flow of this set of equipment are customized according to customer requirements, the final interpretation right belongs to qin tai sheng water treatment all

...

-

Hubei some electronic technology co...

Technical design guidelines

The design of this water treatment process is based on full consideration of the following factors:

2.1 users' requirements on the quality and yield of product water;

2.2 reliability of process design;

2.3 simplicity of equipment and intelligent operation;

2.4 investment and operating expenses;

2.5 physical and chemical cleaning of equipment;

2.6 stability of water quality;

2.7 reliable online monitoring means.

The system has requirements on the outside world

3.1 water supply: municipal water supply ≥50m3/h.

3.2 power supply: the user shall transmit the power cord to the electronic control cabinet of the equipment.

3.3 water production: the water produced by the supplier shall be connected to the nearest inlet of the ultra-pure water pipeline of the user.

3.4 site: the user shall provide the equipment area.

3.5 drugs: all drugs consumed during debugging and operation shall be provided by users.

The technological requirements

4.1 raw water quality: local municipal tap water standard (conductivity ≤200us/cm)

Effluent is 4.2: equipment processing level 1 reverse osmosis conductivity after 20 us/cm or less, secondary reverse osmosis conductivity 5 us/cm or less, terminal EDI water resistivity Ω 15 m * cm or more

4.3 system water output: the water output of the first-stage reverse osmosis pure water machine system is 30m3/h-35m3/h (old equipment: now there is a set of single stage 15 tons + double stage (first stage 14 tons + second stage 6 tons), the water output of the second-stage reverse osmosis pure water machine system is 20m3/h (newly added), and the designed water output of the terminal EDI (electric desalination) system is 18m3/h-20m3/h.

The design principle and process flow of this set of equipment are made according to the requirements of users, and the final interpretation right belongs to qin tai sheng water treatment

...

-

技术设计导则

本套水处理工艺的设计是基于充分考虑下列因素的基础上制定的:

2.1、用户对产品水的质量和产水量的要求;

2.2、工艺设计的可靠性;

2.3、设备的简便性与运行的智能化;

2.4、投资和运行费用;

2.5、设备的物理与化学清洗功能;

2.6、产水质量的稳定性;

2.7、可靠的在线监测手段。

系统对外界要求

3.1 供水:为市政自来水且供水≥30m3/h。

3.2 供电:由用户将电源线输送至设备电控柜上。

3.3 产水:供方产水接至使用方超纯水管路就近进水口。

3.4 场地:由用户提供设备摆放面积。

3.5 药品:调试及运行过程中所消耗的药品均由用户提供。

工艺要求

4.1 原水水质:当地市政自来水标准(电导率≤300us/cm)

4.2 出水水质:设备处理之后一级反渗透电导率≤10us/cm,二级反渗透电导率≤5us/cm。

4.3 系统出水:一级反渗透纯水机系统产水 20m3/h,回收率 65-70%,二级纯水机产水 15m3/h,回收率 80-85%。

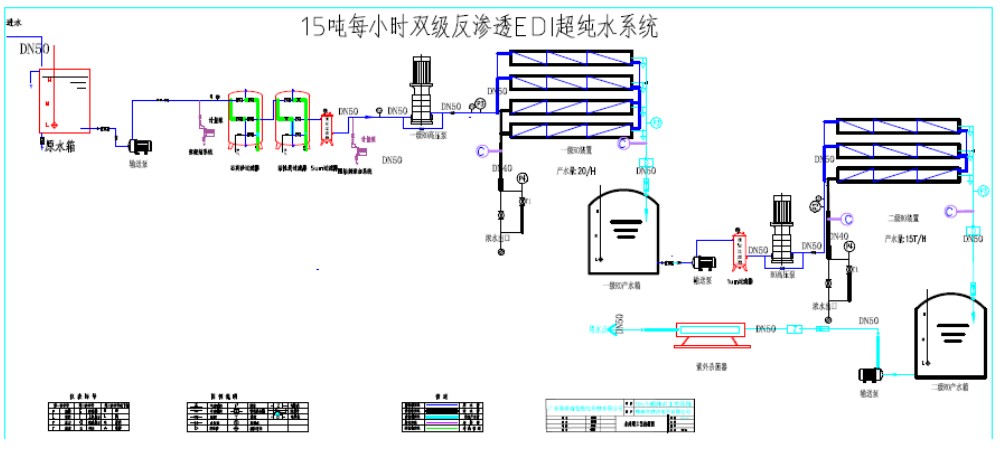

工艺流程平面图:

本套设备的设计原则和工艺流程均是按照客户要求制作,最终解释权归秦泰盛水处理所有

...

-

Zhuhai electronic co., LTD. 15 t/h ...

Technical design guidelines

The design of this water treatment process is based on full consideration of the following factors:

2.1 users' requirements on the quality and yield of product water;

2.2 reliability of process design;

2.3 simplicity of equipment and intelligent operation;

2.4 investment and operating expenses;

2.5 physical and chemical cleaning of equipment;

2.6 stability of water quality;

2.7 reliable online monitoring means.

The system has requirements on the outside world

3.1 water supply: municipal water supply ≥30m3/h.

3.2 power supply: the user shall transmit the power cord to the electronic control cabinet of the equipment.

3.3 water production: the water produced by the supplier shall be connected to the nearest inlet of the ultra-pure water pipeline of the user.

3.4 site: the user shall provide the equipment area.

3.5 drugs: all drugs consumed during debugging and operation shall be provided by users.

The technological requirements

4.1 raw water quality: local municipal tap water standard (conductivity ≤300us/cm)

4.2 effluent water quality: after equipment treatment, the conductivity of primary reverse osmosis is ≤10us/cm, and that of secondary reverse osmosis is ≤5us/cm.

4.3 system effluent: the system of the first stage reverse osmosis pure water machine produces 20m3/h of water with a recovery rate of 65-70%; the system of the second stage pure water machine produces 15m3/h of water with a recovery rate of 80-85%.

The design principle and process flow of this set of equipment are made in accordance with the requirements of the customer, and the final interpretation right belongs to qin tai sheng water treatment

...