- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

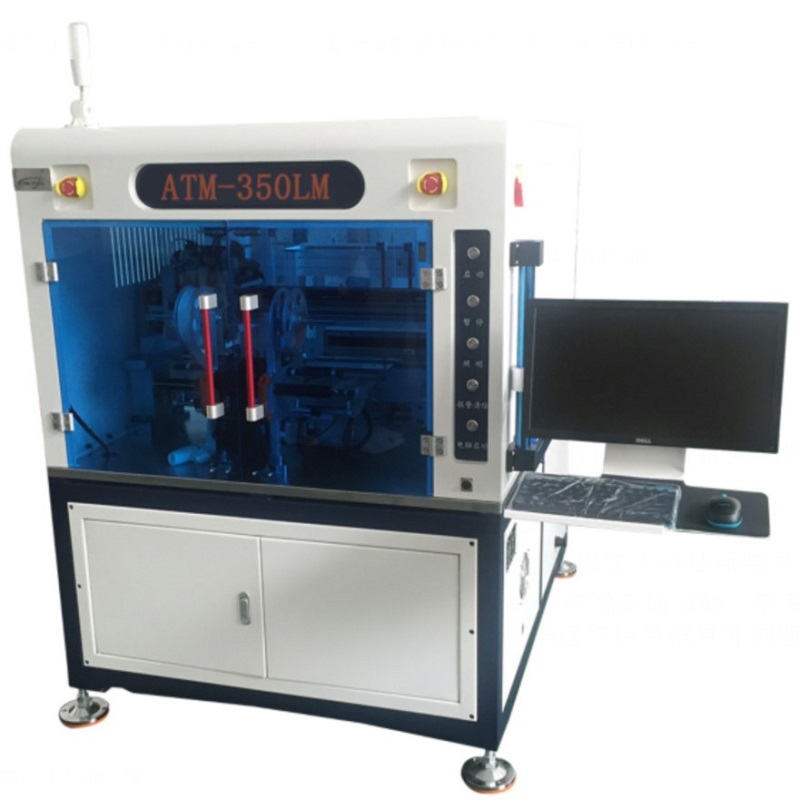

Automatic battery labelling machine

- Product:Automatic battery labelling machine

- Catalogue:Labelling machines

- Views:178348times

- Update:2019/7/24 15:08:32

- Call:133-6065-4218

Equipment name: Automatic battery labeling machine, automatic labeling auxiliary material

machine for cylindrical batteries, automatic labeling machine for 18650 batteries

Manufacturer: Guangdong Qintaisheng Intelligent Technology Co.

Automatic battery labeling machine features.

Automatic battery labeling machine 1 person can complete the operation, manual integration of

the battery into the equipment inside, before laminating can simultaneously accommodate three

boxes of batteries to be mounted, enhance the flexibility of personnel involved

Automatic battery labelling machine is compatible with the production of 38PCS,

50PCS and 100PCS battery boxes; easy to adjust, three battery specifications are switched by

quick plugging and unplugging, and the hardware identifies three different specification markings

to facilitate operations.

Battery box in the labeling process, the structure with clamping function, to prevent the battery

in the box left and right shaking.

automatic battery labelling machine equipped with two sets of upper and lower CCD detection

system for precise placement of insulating rings.

accurate positioning of the labeling material tape and automatic alarm prompt after use.

The whole box slides onto the customer's desktop after the insulating ring has been applied at

the receiving end and is collected manually.

The automatic battery labelling machine is a mobile machine, installed with castors + anti-vibration

foot support, to facilitate the movement of equipment and ensure the stability and reliability of the

machine.

Fully automatic battery labelling machine with the following functional advantages.

Battery box transfer mechanism: The material box transfer mechanism consists of the material to

be transferred and the labeling material + sending out mechanism, using high strength

anti-static, wear-resistant belt and high precision stepping motor with high precision Omron

sensor to ensure the accuracy and stability of the material.

Battery box clamping mechanism: The battery box clamping mechanism is made up of X and Y

directional mechanisms in the form of cylinders to ensure the stability of the battery in the battery

box mounting process; the design is simple and reliable, and the screen printing logo is clear at a

glance, which greatly facilitates the operator to change the material and shortens the time of

changing the material.

Fei Da component: the feeding mechanism is designed and processed by our own research and

development, using high precision stepping motor and high sensitivity optical fiber sensor to

ensure stable material discharge.

Labeling mechanism: The labeling assembly adopts high speed and high precision screw guide +

Panasonic servo motor, the Z-axis adopts Panasonic servo motor drive + our own design high

precision suction nozzle rod module; the head adds longitudinal trim module to ensure

placement accuracy; the high quality vacuum generator is used to ensure the stability of suction

material.

Vision system: the vision system contains 1 set of CCD vision for the top shot battery and 2 sets

of CCD vision for the bottom

shot protective film; the CCD camera adopts the brand product of German Yingmei Jing with the

gigabit network card to transmit data; the high precision CCD camera provides high precision

visual alignment for the whole machine combined with our company's independent knowledge

product software system to ensure high precision placement.

Motion control system: The industrial grade PC industrial control machine and the Raytheon

motion control card are used to do the program control of the whole machine combined with

the company's independent control software to ensure efficient and stable operation of the

equipment, which can also be customized according to customer requirements.

Electrical control system: motion control, relay, servo control, air switch, short circuit switch,

voltage regulator, etc. are installed inside the machine to save space and ensure safety and

reliability.

Frame + large plate: including the main frame and large plate set, using high standard thickened

square pass welded together.

Dust-proof outer cover: Acrylic + sheet metal baking paint make up the shell of the equipment,

which meets the requirements of a thousand-grade clean room and has a simple and generous

appearance.